-

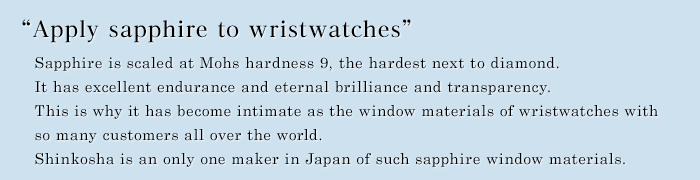

Window Materials for High-class watches:

Features of SHINKOSHA’s Sapphire:

- Crystal growing method:

- the Verneuil method

- Hardness:

- Mohs hardness 9, Vickers hardness 1400 – 2300

- Bending strength:

- 320 – 950 MPa

- Transparency:

- Transmission range 0.2 – 4.5㎛

< High Endurance against Ultraviolet Rays >

Owing to our original technology, you cannot see such coloring in the sapphire crystals that has been caused by ultraviolet rays so far.

-

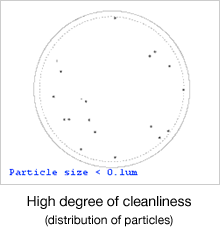

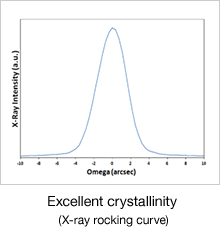

Sapphire Substrates for Blue and White LEDs:

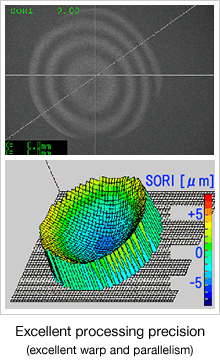

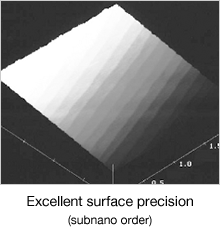

Sapphire substrates are very suitable for thin-film formation of such nitride semiconductors as blue and white LEDs. SHINKOSHA’s sapphire substrates are made of those high-quality crystals which are quite flawless. So, they have no damaged layer, forming high-quality processing surface suitable for epitaxial growth. We can respond to any of your request for various kinds of orientation, off-axis substrates, step surface treatment, etc.

-

Substrates for Epitaxial Growth:

We can offer you such substrates of single oxides that are the most suitable for epitaxial growth of superconductors, compound semiconductors, dielectrics, etc.

You can choose any of our sapphire substrates that best fit for your needs of the crystal system, lattice constant, dielectric, etc. Our advanced precision processing technologies can provide you with our finished products which have such high-quality surface of sapphire substrates that has no flaw nor distorted layers of processing. So, please do not hesitate to consult with us regarding such orientation, form, off-axis substrates, especially specified substrates, etc.

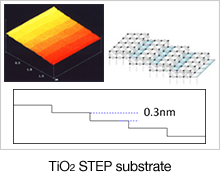

We can also offer you such STEP substrates that have extremely high precision surface, composed of STEPs and a terrace flat at the atomic level. These STEP substrates are made by our original technology which we have developed jointly with the Tokyo Institute of Technology. They are definitely indispensable for adequate growth of epitaxial films.

Crystal Crystal System Lattice Constant (nm) Al2O3 Trigonal

(Rhombohedral phase)a=0.47588

c=1.2992SrTiO3 Cubic a=0.3905 TiO2 Tetragonal a=0.4594

c=0.2958NdGaO3 Orthorhombic a=0.5431

b=0.5499

c=0.7710LaAlO3 Hexagonal a=0.5365

c=1.311MgO Cubic a=0.4213 YSZ Cubic a=0.5139 LSAT Cubic a=0.7736 MgAl2O4 Cubic a=0.8083 YSZ: Yttria Stabilized Zirconia LSAT: (La0.3Sr0.7)(Al0.65Ta0.35)O3

-

Vapor Deposition Sources for Alumina Coating:

We can also offer you vapor deposition sources for thin films of alumina (Al2O3) of high purity.

Features of Our Products:

- Single crystals of high purity (Purity: 99.99%)

- Medium refractive index (1.63@550nm)

As we use single sapphire crystals, our outstanding feature is that gas does not break out at the time of vaporization. Please contact us for inquiring of such alumina vapor deposition sources used for AR coating, hard coating and coating against chemicals that we consistently process, starting from crystallization and ending with precision cleaning.

Item  ES-0510

ES-0510 ES-1020

ES-1020 ES-1035

ES-1035 CS-1030

CS-1030 D13H700T60

D13H700T60Form Crush type Crush type Crush type Cutting type Semidisc type ParticleDiameter 0.5-1.0mm 1.0-2.0mm 1.0-3.5mm 1.0-3.0mm 13mm,15mm,

18mm,20mm -

Window Materials for Transmitting IR and UV Ranges:

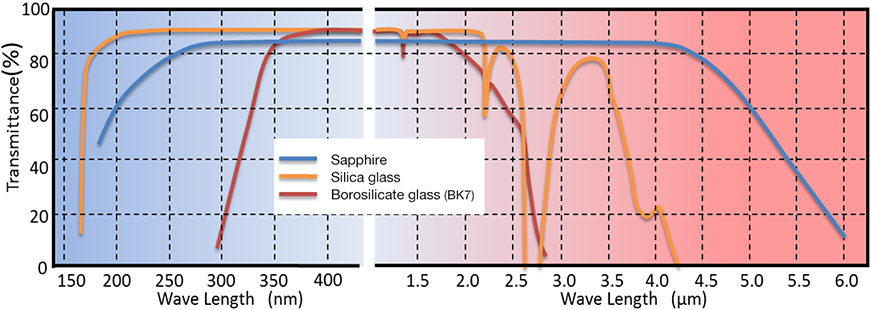

Sapphire windows can transmit a wide range of light ranging from infrared rays (IR) to ultraviolet rays (UV). So, they are widely used for a variety of applications.

-

< IR Range >

Silica glass starts its internal absorption from IR of 2㎛ and then attenuates its transmittance. In contrast, sapphire is stable in transmitting light, so that it is quite suitable for the window materials for various types of IR sensors.

- Examples of applications:

- NDIR gas analyzers, fire detectors, water detectors, noncontact temperature measurement, human detectors, etc.

-

< UV Range >

Sapphire is excellent in thermostability and corrosion resistance as compared with silica glass, so that it is the most suitable for applications against UV in the environment under severe conditions. At the same time, it does not deteriorate like silica glass with long-hour lighting of an excimer lamp (172nm).

- Examples of applications:

- UV hardening, sterilization, chemical concentration meters, photolithography, fire alarms, various types of UV lamps, etc.

-

-

Window Materials for Preventing Scratches:

As sapphire is used for the window materials of wristwatches, it is an excellent material that has a property of high abrasion resistance (Mohs hardness: diamond=10, sapphire=9). So, it is widely used as the industrial materials for preventing scratches.

Examples of applications:

Bar code readers, card readers, coin sensors, water level measuring instruments for rivers, water gates, etc, smart phones, cameras for industrial use, etc.

-

Window Materials under High Temperature and High Pressure:

You can apply sapphire for the window materials which are used in a severe environment under high temperature and high pressure. Its melting point is 2040 ℃ and its strength is more than 5 times as strong as silica glass.

So, you can use sapphire as a view port in the supercritical environment under the condition of high temperature and high pressure. Incidentally, its thermal conductivity is 40 times as much as glass and it can conduct heat nearly as fast as stainless steel.

-

Parts for Manufacturing Equipment of Semiconductors:

Sapphire is an excellent material highly resistant against chemicals and does not melt down by such industrial chemicals as those acids and alkalis which are used in the manufacturing processes of semiconductors. So, it is widely used as the view ports of etching apparatus, ashing equipment, diffusion furnaces, etc. It is also used as those tubes which discharge the activated plasma gas used for etching. Furthermore, the purity of sapphire itself is more than 99.99%, so that it is widely used for jigs and parts in the manufacturing lines of semiconductors.

Weight Change of Sapphire Specimens (25 x 25 x 0.5 mmt) Dipped for 6 Days Acid or Alkali Condition of Exposure Weight Change HCl 35%, 20℃ No change HNO3 50%, 20℃ No change H3PO4 60%, 100℃ No change H2SO4 95%, 100℃ No change NaOH 30%, 100℃ No change HF 46%, 60℃ ⊿=0.0038g/day (very little) -

Parts for Medical Instruments:

Sapphire is a material of very high purity and is not susceptible to deformation, so that it is being studied to apply it for the parts of medical instruments.

Examples of applications:

- Window materials for endoscopes

- Rods for dental laser devices

- Filters for laboratory tests (hematology)

- Dental implants (ceramics mainly used now)

- Sapphire or ruby surgical knives

- Plunger pumps for medical use

- Others

Results of Analyzing Impurities in Sapphire Crystals of High Purity (ppmw):

Ba<0.1 Ca<0.1 Cd*<3 Cr*<2 Cu<2 Fe<1 Hg*<2 K<1 Mg<0.1 Mn<0.5

Mo<5 Na<1 Pb*<10 Si<10 Sr<0.1 Ti=1.8 W<5 Zn<1 Zr<1

*RoHS designated elements (Results of analyzing impurities according to the ICP-AES)

-

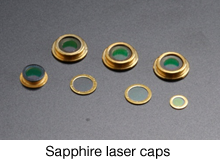

Sapphire Laser Caps (with Coating) for Optical Communication:

We also offer sapphire laser caps as the window materials for semiconductor laser packages. Sapphire is a material of high strength which does not deteriorate under any environmental conditions and is excellent in thermal conductivity. So, it is the most suitable for such a trunk line of electrical transmission system that requires high-power lasers and the performance of high reliability.

At the same time, our products are metalized so as to ensure their high strength and airtight, so that it is easy to join them by Au soldering. Besides, their beam axis accuracy is so high that the dispersion of a polarization extinction ratio is narrow and their optical properties do not deteriorate by our AR coating of high transmission and high reliability. We can also respond to your request for such items of special form that you especially specify for square windows, tapered items, etc.

-

Sapphire Prisms and Lens:

We also process various kinds of prisms by molding and optically polishing our sapphire materials. We finish the polished surface to the highest quality of flatness λ /4 – λ /10. We set the optical axis strictly following your specification, so that you cannot see such birefringence as particular to sapphire crystals. Furthermore, we can respond to any of your request for various types of SR processing and aspheric surface processing by using our curve generator.

Examples of applications:

- Detectors and analyzers using measuring beam with prisms and lens

- Refractometers

- Optical waveguide prisms

- Others

-

Large-size Sapphire Windows:

Thanks to the TSMG method that we have developed by ourselves, we are producing large-size sapphire boules the size of which is the largest in Japan. So, we can offer you various sizes of sapphire products. They are also crystals of extremely high quality, so that you can use them for a variety of applications.

- TSMG boules (about the size φ300mm x 300mmL)

- The size of products that we can cut out:

About the size φ0.3mm x 0.05mmt - φ270mm x 270mmL

About the size □0.3mm x 0.05mmt - 300mm x 200mm x 20mmt

-

Our Unique Products:

These are our unique products made of sapphire or ruby for non-industrial use. We are always creating new novelty products.

HOME>Applications of Sapphire Crystals